|

The ideal media for sustaining flow.

CKC manufactures SF? Filter Cartridges under technical licensed and filter media supply by CKC incorporation.

Process gas filtration is a unique challenge. In addition to potentially high temperatures and, in many applications, caustic elements, there is often the need for sustaining high flow rates and minimizing pressure drop. Fiber metal filtration systems and elements from CKC can provide the solution.

Filter elements composed of metal fiber are extremely stable and offer extended performance without need for replacement. Cartridges are completely welded and are not subject to cracks which can be caused by severe vibrations in chemical filtration systems. In addition, metal fiber elements are easily cleanable and can be used in applications where Cleaning-In-Place (CIP) is required since there is no trespassing of dust when the filter element is cleaned by backpulsing.

High-strength all-metal media High-strength all-metal media

Fiber metal elements are solid and rigid and are, therefore, not subject to any wear by movement or friction. They are also resistant to damage by abrasion of penetrating particles. Fiber filter elements made from 316L stainless steel can be used in environments up to 350??C/650??F, while even higher temperatures can be tolerated with elements made of Inconel 601 (to 560??C/1040??F) or Alloy HR (to 600??C/1100??F ). Through extensive research, fiber elements have also been developed to resist temperatures to 1000??C/ 1800??F through the use of Fecralloy.

High flow and efficiency

Filtration ratings as low as 1μm can be achieved, while even smaller particulate can be filtered out with a high percentage due to dust cake formation. Metal fiber filtration media achieve porosities between 70% and 87%, providing high-efficiency particle capture with minimal pressure drop and maximum flow rates.

Fiber metal features and benefits:

? Heat and corrosion resistant

? Excellent cleaning through backpulsing

? High porosity

? Low initial pressure drop

? Solid construction, enabling high filtration velocities

and long on-stream life

? Broad filtration range available

? Customized dimensions upon design or request

? Flexible in design

? Lightweight elements

? Rigid filtration media

Process gas filtration.

In process gas filtration, the gas stream is heavily laden with solids which must be removed from the filter in place (in-situ), or the filters must remain on line with periodic cleaning in place. CKC precision porous media is ideally suited to this type of service due to its uniform permeability, precise bubble-point control, and mechanical integrity.

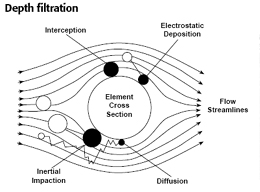

Gas filtration dynamics.

Starting with a clean filter at time zero, the particle capture mechanisms are identical to those of the trap filter. After some time, differential pressure increases as solids are captured on the surface of the element forming a filter cake. This stable surface cake becomes the ?real? filter media. Blowback occurs at a terminal differential pressure which is appropriate for each specific

application.

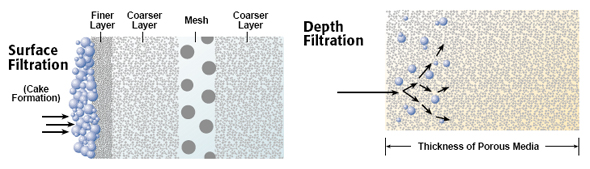

Surface filtration.

Surface filters are a more practical proposition than depth filters for long-term operation of industrial processes with high dust concentrations.

The surface cake is the ?real? filter, which prevents

clogging. Through blowback techniques, periodic cake

removal from the filter surface enables stable operating

conditions without shutdown. Even very fine

particles only penetrate into the surface layer and not

into the support body. A filtration condition will be

reached after a certain number of back-cleaning

actions, which enables a constant residual pressure

drop profile to be maintained.

Final/depth filtration.

Final or depth filtration is generally used in a relatively clean gas stream where there is no need for in-situ blowback cleaning. This type of filtration assures protection of downstream equipment or processes, and protects the downstream system from catastrophic failure of an upstream piece of equipment, or a process upset. Usually a specific nominal or absolute particle-removal requirement is given, along with a clean differential pressure. A particular media can be

selected to meet the removal requirements, and a face velocity is selected to meet the clean differential pressure (and practical process) limits.

In these applications, the filter may remain in service for months, or for the duration of a process campaign.

Then the elements are removed and cleaned for reuse. Cleaning methods can be chemical, controlled atmosphere burnout, or ultrasonic.

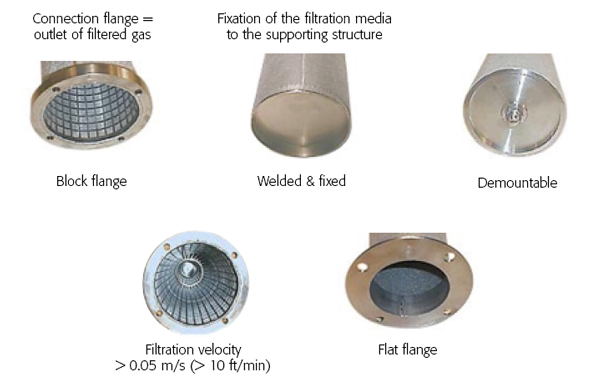

Formed to your specifications

Filter elements made of metal fibers can be customized. The length can vary from 300mm (11.81 inches) up to 3m (9.84 feet). The elements are manufactured with a weld-on metallic carrier in case high filtration velocities must be met. The type of mounting flange of the element on the base plate can be specified by the customer.

Available

Alloys |

AISI 316L SS |

INCONEL 601 |

ALLOY HR |

FECRALLOY |

Maximum

Operational

Temperature |

350-380??C

650-720??F |

560??C

1040??F |

600??C

1100??F |

1000??C

1800??F |

Process applications

Several drivers support the significance of using Several drivers support the significance of using

porous metal fiber in process applications:

? Recovery of highvalue product in a process

? Environmental protection requirements

? Cleaning of process gases before additional use

Hot gas filtration

Fiber metal offers high permeability and low pressure drop, making it ideal for particulate separation in hot gases. Media performance is further enhanced by its excellent thermal-mechanical characteristics, particularly in comparison with ceramics.

Hot gas applications include:

? Catalyst recovery in chemical processes

? Clean process gases in chemical processes

? Clean combustion gases and waste incineration

? Power generation ? coal gasification

Specific applications within specialized industries include:

Petrochemical:

? Polyolefins

? Polypropylene

? Polyethylene

? Melamine

General Chemical:

? Catalyst production

? Nitric Acid

? Pigments

? Others: Acylonitrile, Ammonia, Aniline, Fumed silica, Maleic anhydride

Refinery:

? Fluid catalytic cracking

? Steam cracker

? Continuous catalytic reforming/regeneration

? Catalytic dehydrogenation

Application overview

Because of its high strength, flexibility in form and desirable flow characteristics, fiber metal has been used by many industries in a great number of applications all over the world. Some of these include:

Biochemical industry

Food and beverage sector

Chemical industry

Waste treatment

Pharmaceutical industry

Water treatment

Hot gas cleaning

Chemical and catalyst recovery

Oil and gas filtration

HEPA filter media

Medical and pharmaceutical industries

Nuclear venting

Aerospace

|