|

CKC manufactures SS? Sintered Power Spager under technical licensed by CKC incorporation.

CKC porous metal. There?s no better media for producing miniature, slow-moving bubbles ? the best method of achieving high-efficiency gas/liquid contacting. For decades, CKC porous metal spargers have been the fast, reliable, cost-effective choice for gas/liquid contacting in all sorts of industries. Here are a few reasons why:

Small bubbles transfer gases faster, more efficiently.

CKC spargers introduce gases into liquids through thousands of tiny pores, creating bubbles far smaller and more numerous than with drilled pipe and other sparging methods. The result is greater gas/liquid contact area, which reduces the time and volume required to dissolve gas into liquid.

With thousands of pores over the surface, large volumes of gas can be passed with very high specific area. For example, with equal volumes of gas, 1mm bubbles would have 6.35 times more gas/liquid contact surface area than 6.35mm (1/4") bubbles.

All-metal construction lasts for years.

CKC spargers are constructed entirely of metal, to provide long-lasting operation even in the midst of temperatures as high as 1450??F under oxidizing conditions. And for inert and corrosive media, CKC offers a wide range of materials including 316L stainless steel (standard), Nickel 200, Monel?? 400, Inconel?? 600, Hastelloy?? C-22/C-276/X and Alloy 20.

Conventional drilled pipe spargers (left) produce poorly

dispersed, large, fast-rising bubbles with very low surface area.

CKC porous metal spargers (right) create millions of small,

slowly rising bubbles, with significantly more surface area,

resulting in more complete and rapid mass transfer.

Simple, cost-effective, easy-to-install.

CKC spargers typically consist of a porous metal element, a threaded fitting and, in longer units, a reinforcement rod. The design is simple, without moving parts. Installation is easy, and requires no special tools. From single elements to manifolded systems, CKC spargers are among the simplest, most affordable and most efficient gas/liquid contacting solutions available anywhere.

All sizes and configurations.

CKC spargers are designed, manufactured and finished at CKC. So if you need a non-standard size, or a special fitting, CKC has the capability to accommodate your request.

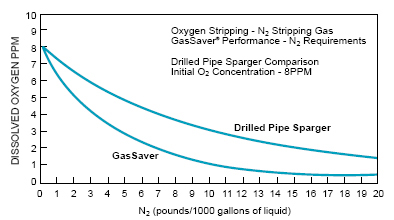

Oxygen stripping, using nitrogen.

Actual performance data shows the superiority of CKC porous metal spargers, compared to drilled pipe spargers. Much higher performance levels with significantly lower gas consumption.

Tank spargers.

In-tank sparging applications can be for batch or continuous operation, with or without agitation within the vessel. CKC sparging technology provides performanceproven designs to assure optimum process operation. CKC spargers are arranged in the bottoms of tanks and vessels in a variety of ways. For smaller tanks, one sparger will often suffice. For larger tanks, several CKC spargers may be manifolded together using a linear or radial pattern to achieve optimal gas diffusion. CKC offers a wide variety of standard tank sparger elements and manifolded assemblies to accommodate most applications. Custom designs are also available by request.

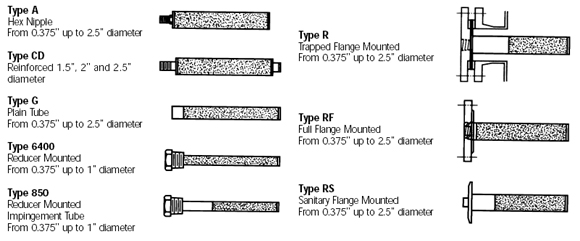

Sparger elements.

Elements larger than 2.5" diameter are available on special order.

Support Studs or Centering Rods on the closed end of elements available if required.

Reinforced elements are recommended for agitated vessels.

Standard materials are 316L stainless steel porous media with 316 stainless steel hardware.

Other materials are available on special order.

Aeration ? Air sparging to meet BOD (Biological Oxygen Demand) on waste stream.

Agitation ? Air injection for mixing liquids in a vessel. Bioremediation ? Air sparging to stimulate growth of bacteria for hazardous waste treatment.

Carbonation ? CO2 sparging for carbonated beverages and beer.

Chlorine bleaching ? Chlorine sparging for bleaching pulp in manufacture of paper.

Column flotation ? Air sparging for coal flotation, and other separations of solids.

Dewatering ? Nitrogen sparging to remove entrained water from motor oil.

Fermentation ? Oxygen or air sparging to enhance cell growth in fermentation reactions.

Gas/liquid reactions ? Sparging air, oxygen, or other gases into reactors for improved performance.

Hydrogenation ? Hydrogen sparging for a broad spectrum of chemical hydrogenation reactions.

Oil flotation ? Air or natural gas sparging for oil removal from produced water from oil wells.

Oxygen bleaching ? Oxygen sparging for bleaching pulp in manufacture of paper.

Oxygen stripping ? Nitrogen sparging to remove oxygen from edible oils, wine, and juices.

Oxygenation ? Oxygen sparging in fish farming for significant stimulation of fish growth.

Ozonation ? Ozone sparging to sanitize ultrapure water systems in pharmaceutical plants.

pH control ? CO2 or NH3 sparging to adjust pH in waste or process streams.

Steam injection ? Direct steam injection for efficient heating, and to eliminate ?steam hammer.?

Volatiles stripping ? Air sparging for removal of VOC (Volatile Organic Compounds) from waste streams.

Call for a recommendation and a quote.

Let CKC identify the right sparger for you, so you can compare performance and cost to what you?re using now. Just tell us the answers to these basic questions:

1. Application

2. Type of containment (tank or pipeline)

3. Gas information

a. Type

b. Flow rate (ft3/min for all gases; lbs/hr for steam)

4. Liquid information

a. Type

b. Temperature

|