|

CKC has continuously improved technology

and widened range of products to serve customers. Moreover, CKC has delivered

various type of Automatic Filtration System, Pressure Vessel, SCR (Selective

Catalytic Reduction) System, Auto Strainer, Metallic Filter Cartridge and Gas

Dehydration System.

|

|

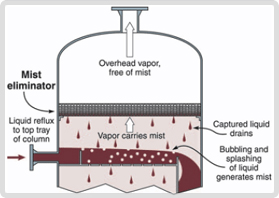

In every process involving contact between liquid and

flowing gas, tiny mist droplets are carried away with the gas. This phenomenon

is called entrainment.

Beginning about 1947, special devices were

developed to remove mist from gas streams. Now known as mist eliminators, these

devices provide a large surface area in a small volume to collect liquid without

substantially impeding gas flow. Unlike filters, which hold particles

indefinitely, mist eliminators coalesce (merge) fine droplets and allow the

liquid to drain away. Gas typically flos upward through a horizontal mist

eliminator.

More recently, advances in technology have enabled

substantial progress in mist eliminator designs, materials, and application

expertise. New products and methods of use have been found highly effective for

many purposes, especially the following:

? Increasing throughput

?

Downsizing new vessels

? Improving product purity

? Cutting operating

costs

? Reducing environmental pollution

? Reducing downstream

corrossion

? Increasing recovery of valuable liquids

In today?s era of

higher expectations of mist eliminators, achieving such benefits requires better

knowledge on the part of users. It is no longer adequate for a designer simply

to indicate ?mist eliminator? in a drawing. The results will depend on proper

specification of mist eliminator type (or combination of types), orientation,

thickness, internal details, support and spacing in the vessel, vapor velocity

and flow pattern, and many other considerations.

Despite the advances

that have been made, mist eliminator specification is still as much art as

science. For all but the most experienced users, proper application depends on

consultation with a manufacturer?s engineers. Such help should be considered for

every new mist eliminator application as well as every upgrade or

debottlenecking of existing applications.

TO MAKE THE MOST of a mist

eliminator investment, the designer should become familiar with the

considerations and possibilities involved. Due to the numerous variables

involved in specifying mist eliminators, designers and purchasers should consult

with Amistco?s separation specialists before making a final decision. |

|

| Mechanical |

| Column packing or trays |

5 to 800 μm |

| Sprays |

10 to 1,000 μm |

| Surface evaporation |

3 to 1,000 μm |

| Chemical |

| Acid mists |

0.1 to 15 μm |

| Condensation |

| Blown off heat exchanger surface |

3 to 500 μm |

| In saturated vapor |

0.1 to 50

μm | | | |